“The models that we were outsourcing were not as accurate as what we are getting from our Stratasys printers.”

– Cody Iverson / CDT | President, Iverson Dental Laboratories

View Original Article Here

Download the PDF

Precision Pays Off

It’s no secret that a fundamental tenet of business success is to take care of your customers. Businesses that grow, thrive and attract new customers are usually the ones that embrace this belief. That seems to be the recipe Iverson Dental Laboratories has been following since its start in 1991. A key ingredient is 3D printing, which gives Iverson Labs the speed, cost reduction and accuracy to grow their business by focusing on the needs of their customers.

Growing With 3D Printing

Iverson Dental Laboratories is located in Riverside, California. It is a full-service lab specializing in dental implants, cosmetic dentistry and digital dentistry. The company recognized early on the accuracy and opportunity afforded by digital impression systems. In the early days of the company, however, they initially outsourced the models generated from the scans. It wasn’t feasible to produce them in-house when the technology was first introduced. Even though the models generated from these systems ultimately resulted in more accurate dental appliances, the outsourcing turnaround time wasn’t optimal.

As digital dentistry continued to grow, so did Iverson’s business volume. The ability to 3D print models from digital scans became more practicable. Over time, outsourcing became less ideal. It started making more sense to complete the work in-house. Iverson Labs purchased its first two Stratasys Eden260V Dental Advantage 3D Printers.

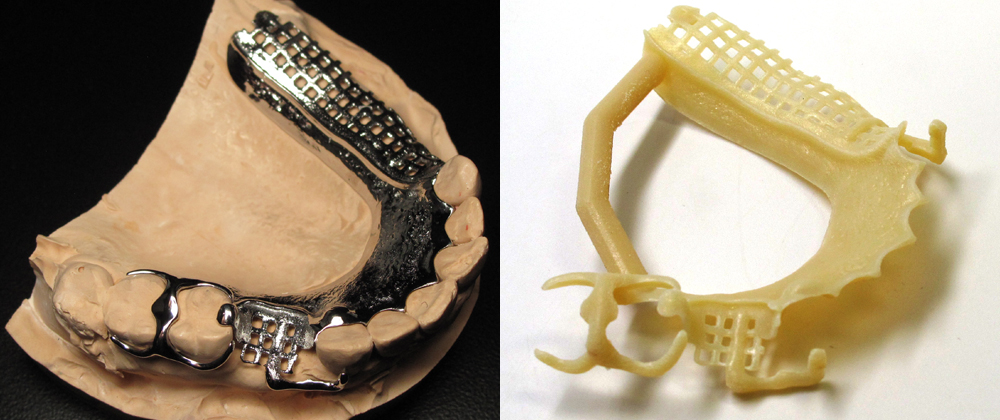

With 3D printing capabilities now in its own hands, Iverson Labs has cut the overall turnaround time required to make appliances and restorations. This allows products to be produced at a lower cost, which creates opportunity for growth. IDL also began to make surgical guides in-house and was able to expand its partial dental framework business.

According to Cody Iverson, company president, “Our price point is a lot better because we can produce (the appliance) a lot cheaper than when we were outsourcing,” a savings that is passed on to customers. Iverson says the removable partial denture business has experienced the most growth. “We’ve been able to cut down on our fees to our clients as well as turnaround time significantly, so that product’s growing really fast.” The combination of this increased capability and a focus on passing the efficiencies to its customers has allowed Iverson to gain more clients.

Accuracy is a Key Component of Success

A dentist’s greatest expense is the time spent with the patient, known in the industry as “chair time.” One driver of chair time includes fitting patients’ restorations and dental appliances. When little to no adjustments are needed, chair time is decreased. Ill-fitting appliances and restorations require “remakes,” meaning the lab must make physical adjustments or remanufacture the appliance. This means another patient visit, more chair time and the additional time and cost for lab work.

According to Iverson, the accuracy of 3D printing is one of its main benefits. “The models we were outsourcing were not as accurate as what we are getting from our Stratasys printers,” said Iverson. He continued, saying the accuracy of the Stratasys 3D printers “helps us maintain one of the lowest average remake (rates) in the industry,” because an accurate restoration starts with a precise 3D printed model.

As a result, Iverson Labs customers report that it takes less than five minutes to seat crowns and bridges due to the accuracy and overall quality of the restorations. Less chair time per patient means dentists can see up to five more patients per day on average, adding revenue. Iverson goes on to add that “Doctors can actually make more money by having things made more accurately, (and 3D printing) plays a key role in that.” This ultimately helps grow Iverson Labs’ business because of the customer-centric and quality-focused reputation it portrays within the industry.

Patients are a dental firm’s greatest asset, and quality service usually results in patient retention and referrals. This same model applies to dental labs. As Iverson Labs has demonstrated, a focus on quality, combined with the accuracy of 3D printing means it can provide its dental practitioners a level of service that solidifies its reputation in the industry, leading to additional business opportunities. According to Cody Iverson, 3D printing helps the company serve their customers better, and that means improved accuracy, turnaround time, and cost.