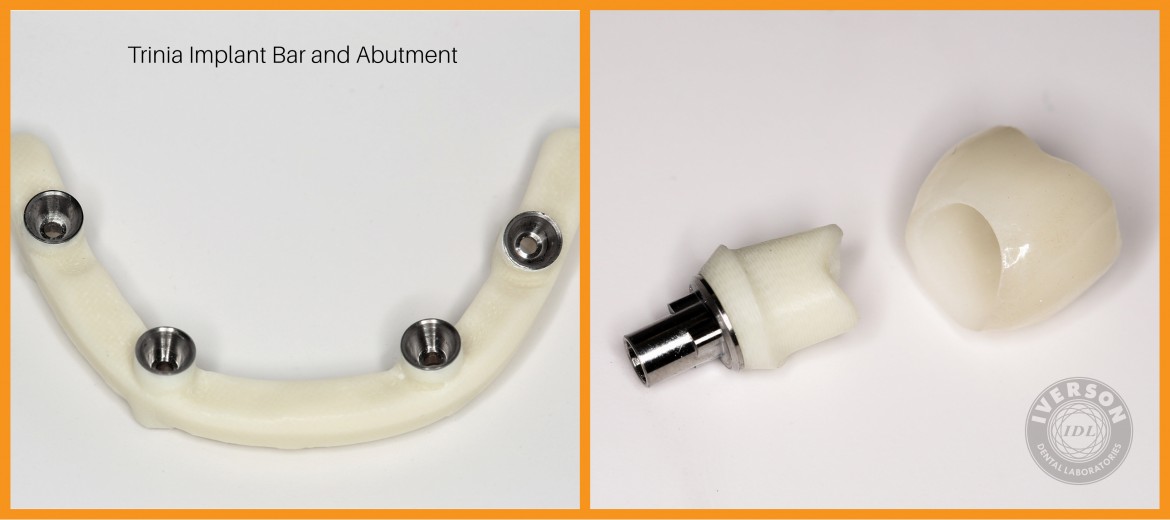

Trinia™ CAD/CAM Discs and Blocks – A Ultralight Alternative to Metal Substructures

Trinia™, a CAD/CAM fiber-reinforced composite, was first introduced in 2010 and has achieved remarkable clinical success and acceptance among dental professionals worldwide. With the growing demand for alternatives to metal substructures in dentistry, Trinia CAD/CAM blocks and discs are the new advanced solution to CAD/CAM metal-free restorations.

Trinia was designed with appropriate mechanical properties as well as proper esthetic characteristics to meet a broad range of clinical indications; resulting in a product with high flexural strength and compressive strength. This resilient and ultralight biocompatible resin material provides dentist and dental laboratories with a more efficient and cost-effective alternative to metal bars milled in titanium, or cast in semi-precious and precious metals

Benefits include:

- Durable and resilient

- Lightweight

- Biocompatible

- Adjustable

- No firing required

- High flexural strength

- Cost-effective alternative to metal

- Unique mechanical properties with high flexural and compressive attributes

Indications of Clinical Use

TRINIA can be utilized for the following indications: copings, substructures or frameworks for permanent and transitional anterior or posterior crowns, bridgework, and substructures that can be either cemented or uncemented restorations, such as telescopic prosthetics.

Trinia CAD/CAM discs and blocks are composed of multi-directional interlacing fiberglass and resin within several layers. Trinia is available in 98mm circular discs, 89mm D-shaped discs, as well as 40mm and 55mm blocks. Following the proper milling procedures, Trinia can be milled on most leading wet and dry milling systems with extreme precision by nano-diamond burs.

Trinia is durable with a flexural strength of 393MPa, compression strength of 374MPa (Parallel) and 339MPa (Perpendicular), and resilient with biocompatible material. Trinia makes their products in the United States, so dental professionals can be assured they are made from high quality materials and adequate manufacturing.

CAD/CAM Recommendations:

- Eclipse design for bars

- Minimum 0.7mm wall thickness

- Minimum 7.0mm2 connector

- Maximum 15mm cantilever

Reference:

https://www.trinia.com/